MANUFACTURING RESOURCES

Sputter Coating

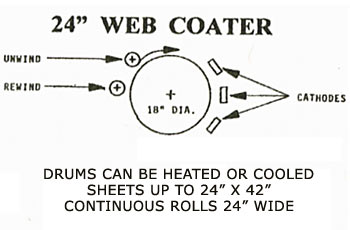

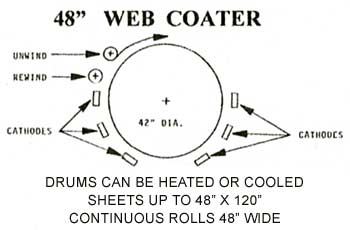

Our thin film vacuum deposition tanks are constructed of stainless steel. They are cryo-pumped, clean, oil-free and capable of pumping to 1x10-7 torr. The main deposition drums may be heated or cooled. The deposition systems consist of planar sputtering cathodes capable of DC and pulsed DC magnetron sputtering. The sputtering supplies include arc suppression equipment to allow easy sputtering of normally difficult materials and reactive processes. Any or all of the systems can be operated simultaneously. Virtually any metal, alloy, semiconductor, metal oxide or nitride can be deposited in combination. Both deposition systems are equipped with quadrapole mass spectrometers and Ocean Optics UV/Vis spectrometers.

SYSTEM ONE can roll coat webs up to 24 inches wide with three cathode capability.

|

SYSTEM TWO can roll coat webs up to 48 inches wide with six cathode capability.

|

| ATU has targets and processes to produce the following sputtered materials. |

Aluminum

Aluminum Nitride

Aluminum Oxide

Chromium

Chromium Oxide

Chromium Nitride

Constantan

Copper

Germanium

Germanium Oxide

|

Gold

Inconel 600

Indium-Tin-Oxide

Lead Oxide

Molybdenum

Nichrome

Nichrome Nitride

Nichrome Oxide

|

Nickel

Niobium

Niobium Oxide

Silicon/Aluminum Alloys

Silicon Dioxide

Silicon Nitride

Silver

|

Tantalum Niobium

Tin

Tin Oxide

Titanium

Titanium Oxide

Titanium Nitride

Specialty Alloys

|

Astral Technology Unlimited, Inc.

1611 Riverview Lane • Northfield, MN 55057-3139

Voice: (507) 645-0935

Fax: (507) 663-8807

Email: atu@clear.lakes.com

|